When the tank has been emptied of its CO2 liquid content, the Survitec deactivation procedure maintains the internal pressure at approx. 10 bar to remove any risk of tank damage as a result of moisture ingress. This also means the CO2 tank does not need to be opened, inspected, internally cleaned and purged before refilling and reactivation.

- Vessel can go into cold lay-up Instead of hot lay-up – to protect revenues

- Simplifies refilling & reactivation procedures

- Removes risk of tank damage caused by moisture ingress

- Electricity is no longer needed to maintain the pressure for the CO2 LP firefighting systems once Deactivated

- Engineers available at Survitec Key ports with flying squads on-hand if required

TECHNICAL INFORMATION

DEACTIVATION PROCEDURE OVERVIEW

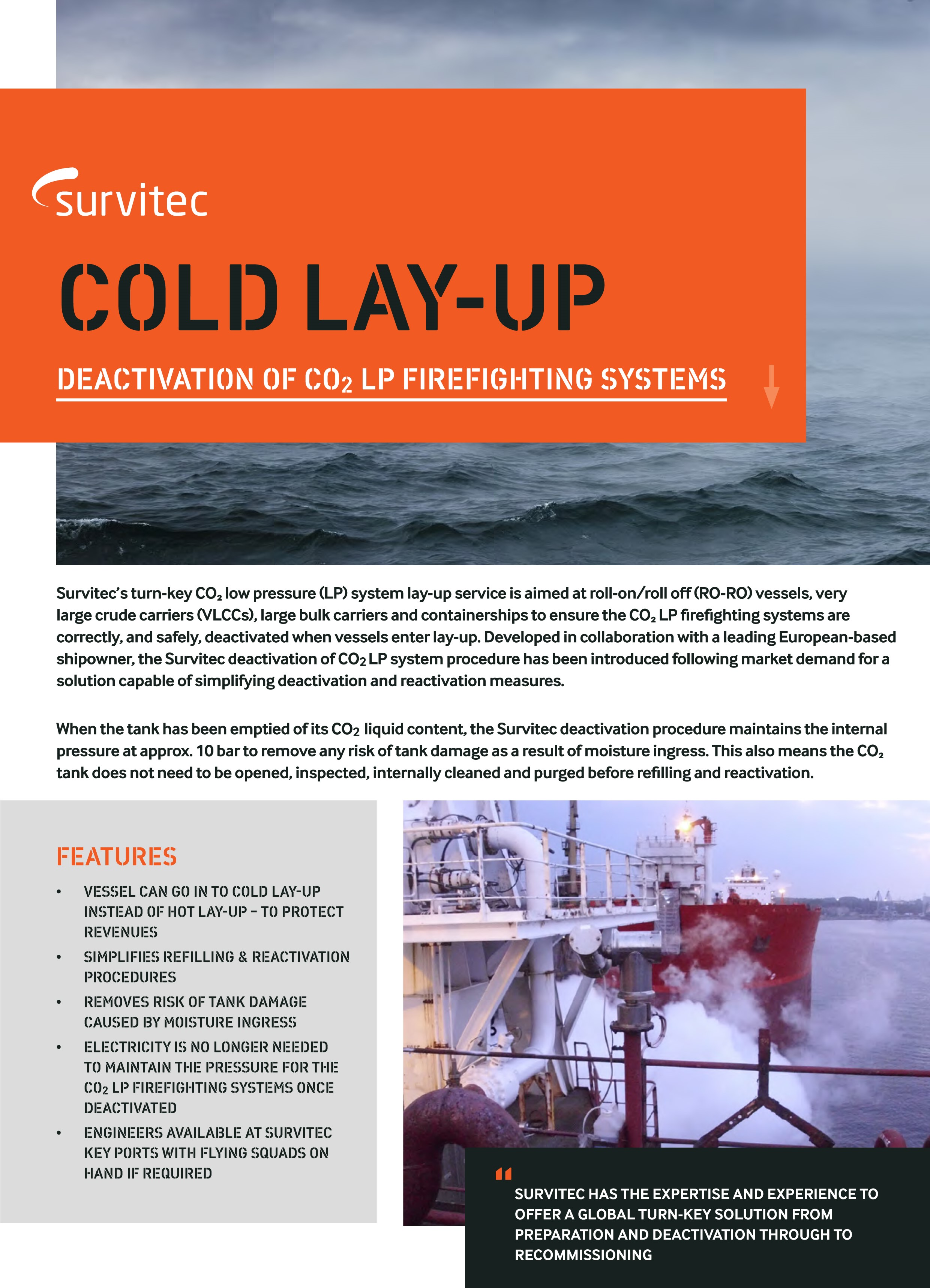

The knowledge and capabilities of the deactivation process are based on the skill set and experience of the Survitec service teams, built up during the periodical services and refilling operations of CO2 LP systems. In addition to stringent ventilation, gas detection and personnel safety requirements, the cooling compressors need to be prepared prior

to tank emptying. Once the compressors are safe, the tank must be emptied through the liquid filling line instead of the gas return line to avoid a rapid drop in pressure and the CO2 turning into a solid block of ice.

The CO2 LP system must be emptied prior to lay-up as the ship’s generators will be shut down and unable to provide any power to shipboard compressors and refrigeration

units.

The safest and most cost-effective way to carry out this work is to move the vessel by tug to a quayside. However, refilling of the CO2 tank at anchorage is possible with good planning and special arrangements.

SERVICING

Survitec is here to support operators and ship owners navigate through uncertain times. It has the expertise and experience to offer a turn-key

solution from preparation right through to reactivation including:

- Emptying of CO2 tanks

- Pressure testing of CO2 tanks & replacement of some parts

- Cleaning of CO2 tanks

- Reactivation (filling) of tanks with CO2

- Servicing of firefighting system / reconfigure alarms systems etc.

RULES AND REGULATIONS

Survitec has Z17 approvals as service suppliers – from various classification societies allowing it to service and maintain a vessel’s multi-branded fire-extinguishing systems, including CO2 LP systems. Only when the responsible classification society has given the relevant approvals, can the reactivation procedure of the CO2 LP firefighting system take place.