|

|

Key Features

- Cylinders and accessories are subject to less physical damage

- Location of cylinders is known to everyone on board

- Cylinders can easily be removed in case of a fire on board

- Gas is available simultaneously from several cylinders when needed

- Sufficient gas flow for all welding / heating / cutting purposes

- No interruptions during work due to change of cylinders

- Gas pressure adjustment at the outlet station, shorter hoses, and no cylinder transport to the worksite

- The total number of cylinders on board is reduced

- Regulators, flashback arrestors and hoses

- Improves work efficiency and protects the crew members from long exposure to the physical hazards of transporting steel cylinders, which can weight up to 100 kilos

|

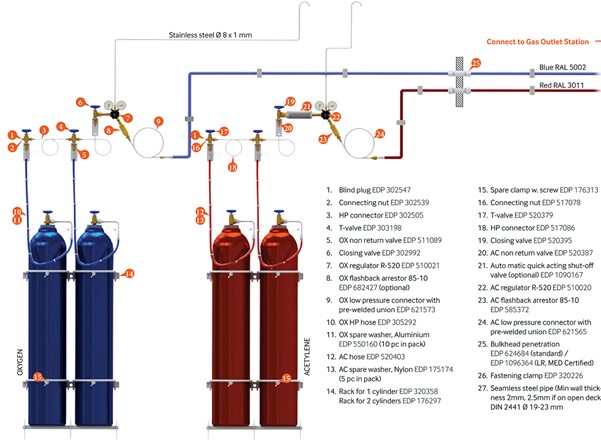

The standard centrals for Acetylene and Oxygen include all items necessary for the gas central room, including signs, racks, equipment and brackets to be screwed or welded to the deck and bulkhead. Also included are pre-welded unions to be welded to the distribution pipes, and brazed to the evacuation pipes from the regulator safety valves. The cylinders and outlet stations must be ordered separately. NOTE: Gas cylinders, cylinder trolley, clamps, bushings and outlet station to be ordered separately. If central is to be placed in two separate rooms (one for acetylene, one for oxygen) the following extra signs are needed: 183202, 526566 and 526558.

|

|

TECHNICAL INFORMATION

System Description

The gas distribution central includes all items necessary for the gas central room, including signs, racks, equipment and brackets to be screwed or welded to deck and bulkhead. The system includes pre-welded unions to be welded to the distribution pipes, and brazed to the evacuation pipes from the regulator safety valves. Gas cylinders, cylinder trolley, clamps, bushings and outlet stations should be ordered separately in necessary quantities.

It shall be installed in a separate, ventilated room. Up to 8 cylinders, can be stored in the same room. If there are more cylinders, there shall be one room for acetylene and one for oxygen.

The cylinders are fixed to the central, and connected to high pressure mainfolds with flexible high pressure hoses. The manifold leads the gas to a central pressure regulator, where from the gas is distributed through fixed piping to the various gas outlet stations onboard.

The safety valve of the central regulator must be connected to a pipe to carry any escaping gas out on the open deck.

Gas Outlet Station - Model R-700

The Survitec outlet station model R-700 for bulkhead mounting is designed to obtain the highest degree of safety together with ease of operation. The standard protective cabinet, which completely encloses the outlet equipment, is made of 1.5 mm steel plate. For open deck mounting, a fibreglass cabinet is recommended - this strong cabinet is designed to give a high degree of protection. It is corrosion-proof, with stainless steel hinges and lock. As standard supply, the outlet station is fitted with the completely enclosed SG-5 flashback arrestors. Alternatively it may be fitted with model S-55 or W-66S flashback arrestors. The outlet stations are delivered complete with installation instructions and directions for use and maintenance. A stretch-relief bracket for the welding hoses is included.

Signs for Gas Distribution system

The signs are in accordance with the requirements of the Norwegian Maritime Authority and NS 6033, with both Norwegian and English text. The instruction signs for Acetylene and Oxygen in the gas central have texts in English, German, Spanish and Norwegian. The signs are printed in black on thick yellow plastic and may be attached to the bulkhead by means of screws or glue.

Related offers