A turnkey lifeboat project commissioned by Shell UK showcases Survitec’s unique service offering and the breadth of its engineering expertise.

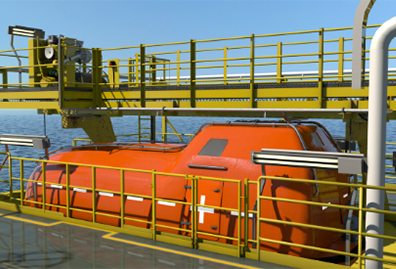

Shell UK asked Survitec in May 2018 for a turnkey solution to increase lifeboat capacity on the Shearwater gas hub by more than 22%. Survitec’s solution was to replace the existing three 49-person capacity lifeboats, with three 60-person lifeboats taking the total capacity from 147 to 180.

The project was driven by an anticipated upturn in activity offshore, including a major offshore turnaround planned for 2020, which made provision of additional offshore bedding capacity a priority to allow the safe and efficient running of the Shearwater asset. However, given that both the SOLAS (Safety of Life at Sea) Convention and the UK’s national regulatory body HSE (Health and Safety Executive) have strict rules governing safety, the uplift in personnel at the hub required an increased lifeboat capacity.

Lack of crane coverage and a compressed project delivery schedule were just two of the challenges Survitec and the project team overcame, as they commissioned three new lifeboats and modified davits on the Shearwater platform during 2018.

Andrew Sinclair, Shell Project Manager said: “This project was a priority for the Shearwater Asset allowing for a ramp up in project and maintenance activity to help unlock the platforms potential and secure a bright future for the facility.”

As Survitec’s 60-person lifeboats are larger than the existing boats, the existing davits were too small for the new inventory so had to be replaced. The marine offshore safety specialist had only a two-month window in which to deliver, install and commission the new equipment.

Access was also tricky. The position of the lifeboats on the hub did not allow for crane access, and hot work on site was prohibited. Further, only one lifeboat at a time could be taken out of service, adding to the logistical complexity to the project.

Marc McEwan, Head of Projects, Survitec, said: “We knew from the outset that this was a challenging project that needed a different approach to meet the tight timeline. Allocating the right resources from the start were key to the project’s success. Crane access to the site was limited, so we also had to gather the correct information and detail to enable the overall plan to develop before we installed the davits and rolled out the lifeboats in the two-month window.”

McEwan explained that Survitec’s first step was to carry out a 3D survey of the Shearwater platform so Survitec could better understand the layout of the site and any access limitations. The three lifeboats would sit in the same location as the existing boats, parallel to each other along one side of the hub.

The 3D survey, however, showed that new longer davit maintenance platforms were required to support the larger lifeboat. These new top sections were designed, fabricated and tested onshore by Survitec over a four-week period, witnessed and approved by Lloyd’s Register.

During the installation phase Survitec worked in tandem with Zenith Structural who developed a bespoke lifting arrangement to get the new top sections and ancillary equipment into position for final installation.

McEwan said: “Moving both the davit top sections and lifeboats into their positions was one of the more complicated aspects of the operation, but Shell UK’s team of technicians and the wider support team were brilliant to work with and completely understood the platform’s access limitations and the North Sea weather.”

Survitec had access to the rig during September and October last year. It drew upon its lifeboat design expertise, regulation insight and fulfilment knowledge to deliver the full scope of the project on deadline.