MES reliability

Discover how reliability applies to the whole through-life supply of marine evacuation systems, from design through to testing, manufacturing, delivery, commissioning, as well as operational servicing and MES training.

Exceptional design

Whether designing a brand-new marine evacuation system or modifying existing products, it starts with design, applying clear methodology carefully reviewing data and drawing on experience and lessons to enhance our MES design. Throughout the design phase our highly experienced team works to clearly defined objectives actioned in a strict project management process.

Tested to the limits

Following the design phase, detailed prototypes are created and extensively tested to engineer out any problems ensuring the design objectives are met. In accordance with SOLAS, all MES are tested to MSC 81(70) heavy sea conditions. These trials simulate real-life emergency scenarios putting tremendous strain and pressure on the systems in force 6 winds with minimum 3-metre wave heights. Once successfully passed, the product moves into the manufacturing phase.

Industry approvals and standards

Once an MES successfully passes heavy weather sea trials, the system enter a rigorous process to obtain approval from worldwide class and flag societies. We’re the only company to hold ISO 9001, MED Mod B & D, and AS 9100 Aero standard certifications. This means every MES we manufacture meets the higher AS 9100 Aero standard by default.

Quality manufacturing

To ensure product quality and consistency we continually monitor the manufacturing process with both internal and independent teams in place to perform in process inspection and testing, as well as end of line testing. We also have cross-functional reviews built into the process providing opportunities to ensure we deliver on quality of our processes and the end product.

Packed & stowed with care

To mitigate the risk of human error once the marine evacuation system have been manufactured, Survitec employ packing and stowage teams utilising an in depth instructional checklist along with a buddy system to ensure conformity throughout this key process. As an extra measure, we also have an independent marshal process in place for all packing and stowage loading activity.

Expert installation & deployment

Successful installation of systems is vitally important. If any one component does not perform, it could jeopardise the integrity of the MES completely not to mention the lives of those who depend on it in an emergency. It is imperative that MES are correctly installed. During this stage, any issues no matter how small are captured in our robust 5Y and corrective action process to understand and deal with the root cause of any problems.

Consistent servicing levels

Survitec take responsibility and care for our customers seriously right the way through the vessel’s life. Regardless of location, our highly trained MES service technicians adhere to Survitec’s meticulous standards. Two approved technicians must sign off any work undertaken. To maintain service station standards, Survitec audits all stations every three years as a minimum and for our larger MES solutions, we audit these approved service stations annually.

Comprehensive training solutions

In addition to building systems and procedures to ensure reliability, we provide comprehensive crew training solutions either onshore or on-board customer’s vessels. These courses cover operational procedures required to deploy the marine evacuation system. We also provide system manuals and training videos.

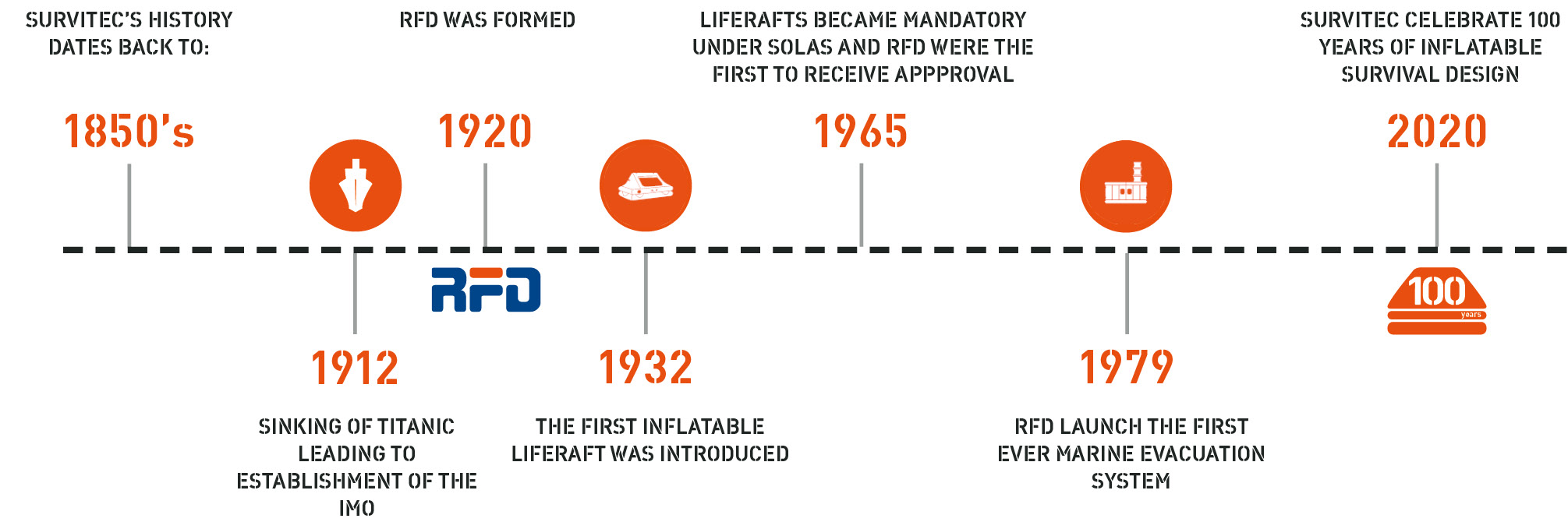

100 YEARS AND COUNTING OF BEING BUOYANT IN SURVIVAL

Survitec’s roots trace back over 160+ years with 2020 marking 100 years since the introduction of inflatable survival technology. Our fascinating MES story starts some years later in 1920, when Reginald Foster Dagnall, an experienced balloonist and airship pilot, put his engineering flair and innovative thinking to work founding RFD (now known as Survitec).

.