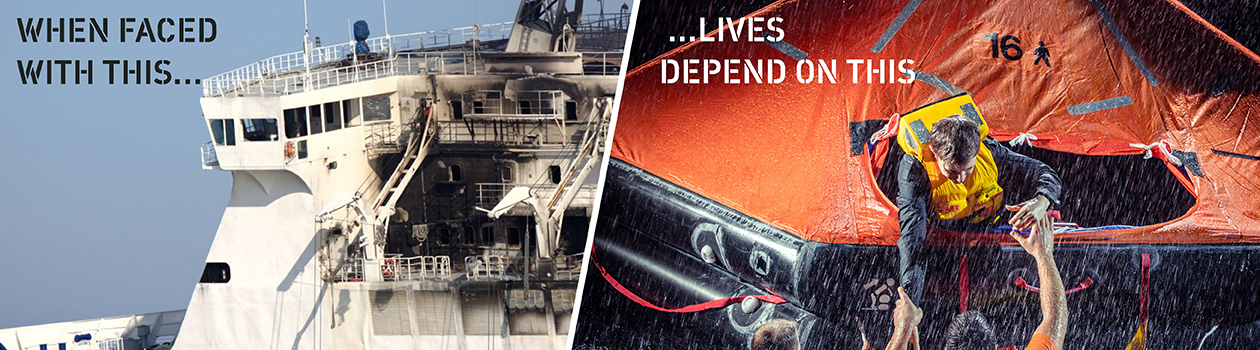

Should disaster strike,

you need a liferaft you can depend on. The ability to abandon ship quickly and protect the lives of your passengers and crew is paramount. At Survitec, we have an in-depth understanding of our customers' needs. Our knowledge and expertise have earned us a reputation for delivering safe, strong and reliable critical safety and survival solutions. At the heart of this success is our continued focus on reliability at every stage. From design, testing and manufacture - through to delivery, commissioning and operational servicing - we aim for excellence in everything we do. Our meticulous focus is on protecting your people, assets and reputation. This, combined with over 100 years of experience, means you can depend on us to bring you home.

Exceptional design

Products within the marine liferaft portfolio are designed and maintained to the highest standards, drawing on Survitec’s many years of experience as an industry leader in lifesaving appliances.

Throughout the design phase our highly experienced team works to clearly defined objectives actioned in a strict project management process to ensure that a functional and reliable design is achieved.

Tried and tested

Liferaft prototypes are then created and extensively tested to the SOLAS requirements of MSC 81(70) and other relevant standards. This process involves thorough testing of the material choices, construction techniques and the performance of the products in real-life test scenarios. This ensures the design is fit for purpose in severe marine environments. This ensures the design is fit for purpose in severe marine environments.

Industry approvals & standards

Our liferaft designs are subject to approval trials and rigorous tests to obtain approval from worldwide class and flag societies.

Quality & assurance

The robust quality processes set by Survitec ensures that material strength specifications are met. Joints are designed in shear rather than peel to improve strength - and extensive testing is conducted at all stages. To ensure end-to-end product quality and consistency, we carefully monitor the manufacturing process throughout - not only with our own skilled internal employees, but also with independent external teams.

Strict manufacturing process

Manufacturing follows well-documented processes of standard operating procedures, in-stage inspection qualification checks, and pressure testing of the final product. This ensures compliance with SOLAS specifications.

Deployment tests are then carried out to ensure rafts perform as intended in an emergency situation.

Consistent servicing levels

To ensure high-quality customer service, all Survitec-approved service stations are audited and approved to the highest legislative and regulatory standards. Only approved and trained service engineers are authorised to carry out the work required on Survitec liferafts. These consistent service levels are maintained across over 405 service stations globally serving 2,000 ports.

Packed and stowed with care

Meet our liferaft technician Dave Guy. The loyalty and expertise of Dave and all of our liferaft service technicians are what sets us apart, delivering on our values every day and helping to ensure the ultimate safety of your passengers and crew in the event of an emergency. For optimum performance, our liferafts undergo a strict packing process involving a buddy system to check predetermined critical steps.

RaftXChange - Everything you need, everywhere you need it.

The Survitec RaftXChange liferaft rental and exchange model provides you, our customers, with the ultimate in rental flexibility. With unrivalled global coverage and a range of predictably priced exchange options, you can tailor your liferaft contract, to suit your operational requirements.

When choosing a RaftXChange+ contract with Survitec you are able to significantly improve your operational efficiencies. The novel design allows you to increase your liferaft service intervals from every 12 months to 30 months. This means you only need to complete a liferaft exchange once every five years! Directly resulting in less handling, less time spent in port and ultimately, cost efficiencies for your business.